Steel mosquito nets are typically made of high-grade stainless steel wire (commonly Grade 201,304 or 316), woven into a fine yet extremely strong mesh designed for durability, security, and corrosion resistance.

Material and Composition

Steel mosquito nets primarily use stainless steel wire, with specific grades tailored to different environments.

- Grade 201,304 Stainless Steel: This is a versatile and widely used grade that offers good corrosion resistance in most outdoor applications. It is a strong, low-maintenance option for typical residential use.

- Grade 316 Stainless Steel: Also known as marine-grade stainless steel, this variant includes molybdenum, which gives it superior resistance to chlorides, salt spray, and harsh industrial chemicals. It is the ideal choice for coastal properties and high-humidity areas.

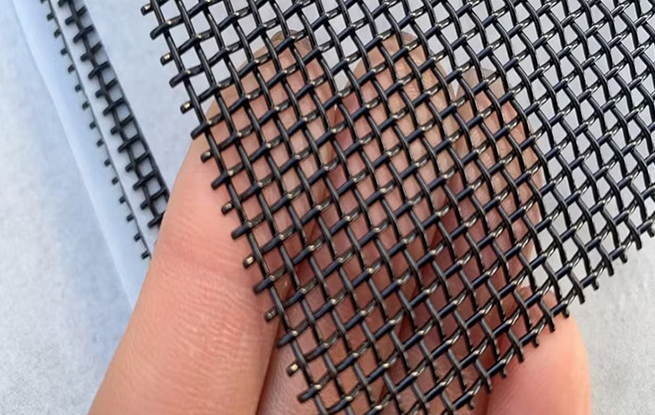

- Coatings: The mesh may be natural silver in color or coated with a black powder finish to enhance outward visibility by reducing glare and improving aesthetics.

Key Specifications

- Mesh Size: The mesh size refers to the number of openings per inch. Standard sizes for mosquito protection include 16x16, 18x16, or 18x18 mesh, which effectively block most mosquitoes and other common insects. Finer meshes (e.g., 20x20) are available for protection against smaller gnats or midges.

- Wire Diameter: This impacts the mesh's strength and rigidity. Common wire diameters range from 0.18 mm to 0.8 mm, with thicker gauges offering greater security and impact resistance.

- Weaving: The most common production method is plain weaving, where wires are interlaced to create a uniform, stable grid pattern.

Advantages and Disadvantages

| Pros | Cons |

|---|---|

| Exceptional Durability: Stainless steel is extremely strong, resists impact, and is highly resistant to tearing or sagging. | Higher Cost: It is easily the most expensive mesh option compared to fiberglass or aluminum. |

| Corrosion & Rust Resistance: It will not rust or corrode, even in harsh weather conditions, especially Grade 316. | Installation:The material is heavy and rigid, often requiring professional installation and specific tools (like wire cutters) to work with. |

| Security: The robust construction provides an added layer of security, acting as a deterrent against intruders. | Potential for Damage: The mesh may dent or kink upon heavy impact. |

| Fire Resistance: Steel is a non-combustible material, enhancing safety in high-risk zones. | |

| Excellent Visibility/Airflow: The fine wire diameter allows for clear outward visibility and good ventilation. | |

| Low Maintenance: Requires only occasional cleaning with mild soap and water. |