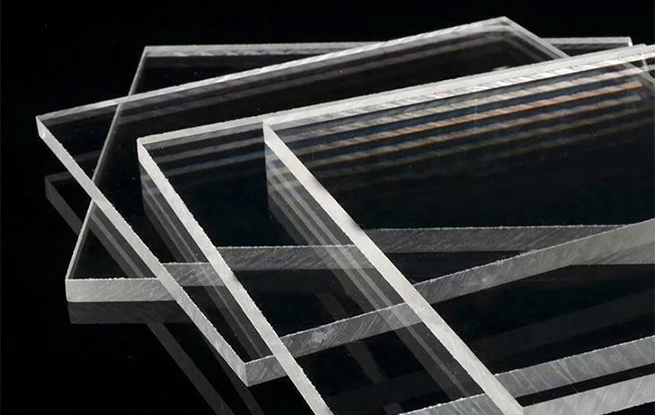

Acrylic sheets, also known by brand names such as Plexiglas® and Perspex®, are a versatile, transparent thermoplastic (polymethyl methacrylate or PMMA) widely used as a lighter, stronger, and more impact-resistant alternative to glass. They are easy to fabricate and suitable for a broad range of indoor and outdoor applications.

Key Properties

Acrylic sheets offer a unique combination of performance characteristics that make them a popular choice across various industries.

- Optical Clarity: Acrylic provides excellent light transmission, with clear sheets allowing up to 92% of visible light to pass through, which is slightly more than glass. It maintains this clarity and does not yellow with prolonged UV exposure, making it ideal for outdoor use.

- Durability and Weight: : It is significantly lighter than glass (about half the weight) yet has much higher impact resistance (often cited as 10 to 17 times stronger). While it can break under extreme stress, it tends to crack into larger, duller pieces rather than shattering into dangerous shards like glass, enhancing safety.

- Weather and Chemical Resistance: Acrylic has superior weathering properties and resists many common chemicals, although it can be damaged by solvents and certain strong acids/alkalis.

- Fabrication: It is easy to cut, machine, drill, and thermoform (shape with heat), allowing for a high degree of customization.

- Aesthetics: Available in a wide range of colors and finishes including opaque, translucent, mirrored, frosted, and non-glare, it can offer a modern, high-gloss look.

Types of Acrylic Sheets

The two main manufacturing methods produce different types of acrylic with distinct properties.

- Cast Acrylic: Manufactured by pouring liquid monomer into a mold, resulting in a high-quality sheet with superior optical clarity, better chemical resistance, and excellent machining characteristics. It is generally more expensive and is often used for high-end applications like aquariums, museum displays, and custom furniture.

- Extruded Acrylic: Produced by pushing melted acrylic through a die, resulting in a more cost-effective material with a consistent thickness. It is slightly softer and more susceptible to scratches than cast acrylic but is easier to thermoform and bond with solvent cements, making it popular for large-scale production and general signage.

Common Applications

Due to its versatility, acrylic is used across many industries.

- Architectural Glazing and Windows:Used for skylights, windows, and transparent facades due to its clarity, impact resistance, and insulation properties.

- Signage and Displays: Widely used for indoor and outdoor signs, point-of-purchase (POP) displays, and brochure holders because of its durability and ability to be colored and lit.

- Protective Barriers: Its shatter resistance makes it ideal for safety shields, sneeze guards, and security glazing in public spaces.

- Interior Design and Furniture: Used for modern furniture, wall panels, partitions, and decorative elements due to its aesthetic appeal and ease of customization.

- Aquariums: Large aquariums often use thick, seamless acrylic panels because of their strength and clarity.

- Transportation: Utilized for aircraft cabin windows, car taillights, and instrument panels due to its light weight and durability.